-

en

- Contact

-

en

- Contact

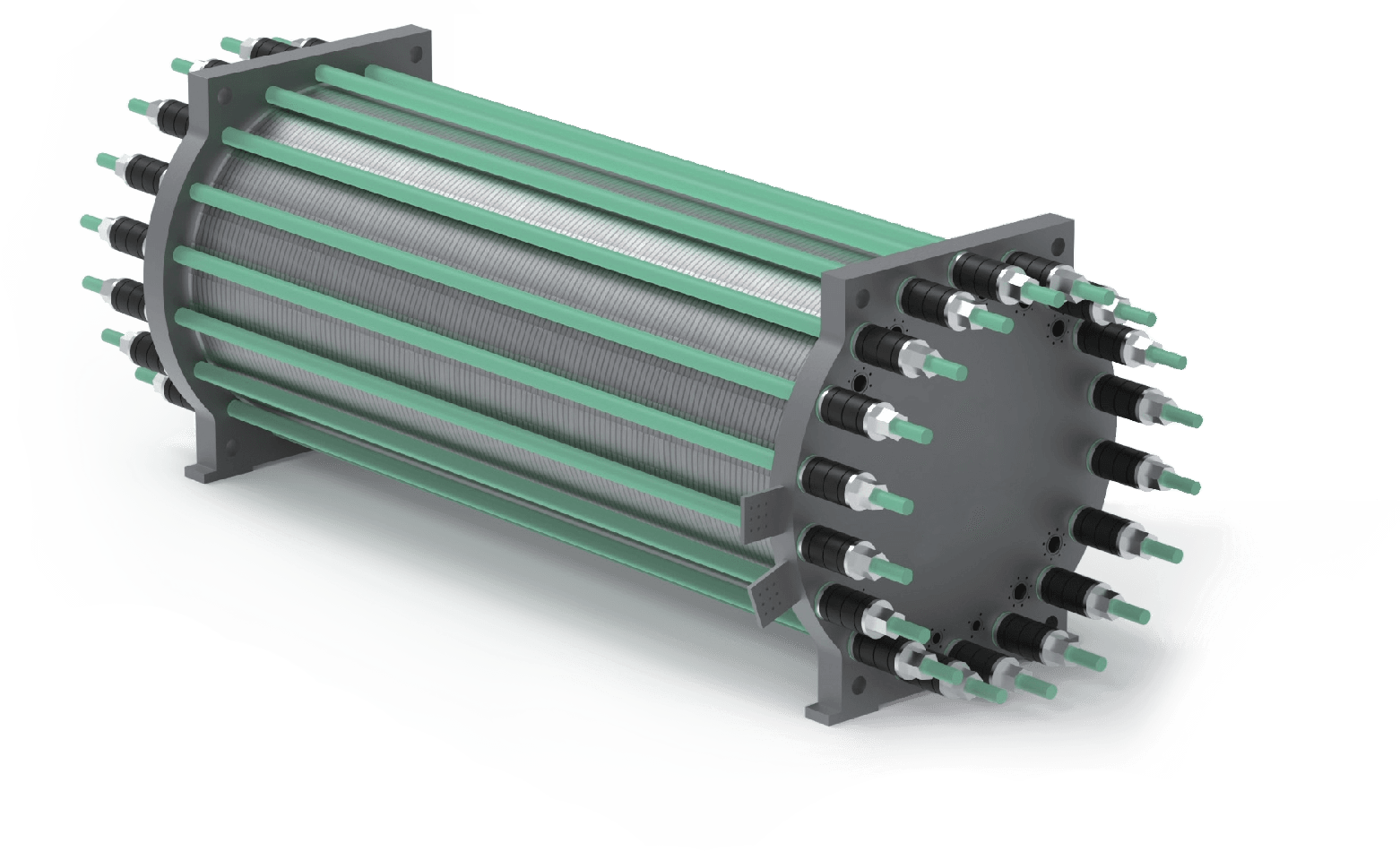

The alkaline electrolyser represents a cutting-edge solution for generating hydrogen by splitting water using an alkaline electrolyte. This innovative process produces hydrogen at the cathode and oxygen at the anode, separated by a durable diaphragm. Recognized for its reliability and cost-efficiency, alkaline electrolysers are a cornerstone of industrial hydrogen production and play a pivotal role in renewable energy systems, driving green hydrogen initiatives worldwide.

Send Inquiry

State-of-the-art optimized electrode structure combined with advanced nickel-plating techniques ensures superior performance and efficiency.

Incorporates new materials and processes to achieve higher current density while maintaining environmentally sustainable operations.

Features optimized gaskets and frame sealing within the bipolar plate design, significantly extending operational lifespan.

An optimized gas-liquid flow field delivers superior flow equalization efficiency for consistent and reliable performance.

Compact and meticulously engineered structure enhances heat exchange efficiency, ensuring energy-efficient operations in diverse applications.

With a focus on innovation, durability, and environmental sustainability, the alkaline electrolyser is a cornerstone technology for industries transitioning toward green energy, offering a reliable pathway to achieving global decarbonization goals.

| Capacity in MW | 250 kW | 500 kW | 750 kW | 1 MW | 1.5 MW | 2.5 MW | 4 MW | 5 MW |

|---|---|---|---|---|---|---|---|---|

| H2 Production Rate | 50Nm3/hr | 100Nm3/hr | 150Nm3/hr | 200Nm3/hr | 300Nm3/hr | 500Nm3/hr | 800Nm3/hr | 1000Nm3/hr |

| O2 Production Rate | 25Nm3/hr | 50Nm3/hr | 75Nm3/hr | 100Nm3/hr | 150Nm3/hr | 250Nm3/hr | 400Nm3/hr | 500Nm3/hr |

| Nominal Pressure | 1.6/3.2MPa | 1.6/3.2MPa | 1.6-2.5MPa | 1.6-2.5MPa | 1.6-2.5MPa | 1.6MPa | 1.6MPa | 1.6MPa |

| H2 Purity | 99.999% | |||||||

| Water Consumption | 1 kg/Nm3 | |||||||

| Power Consumption | 4.1 to 4.3 kW/Nm3 | |||||||

Our Alkaline Electrolyzers Technology Advantages: